Design Customization for Custom Bags

OEM / ODM Development for Global Brands

From concept, reference, or tech pack to sampling and bulk production — XINZIRAIN delivers end-to-end custom bag development with clear timelines, controlled quality, and full supply-chain support.

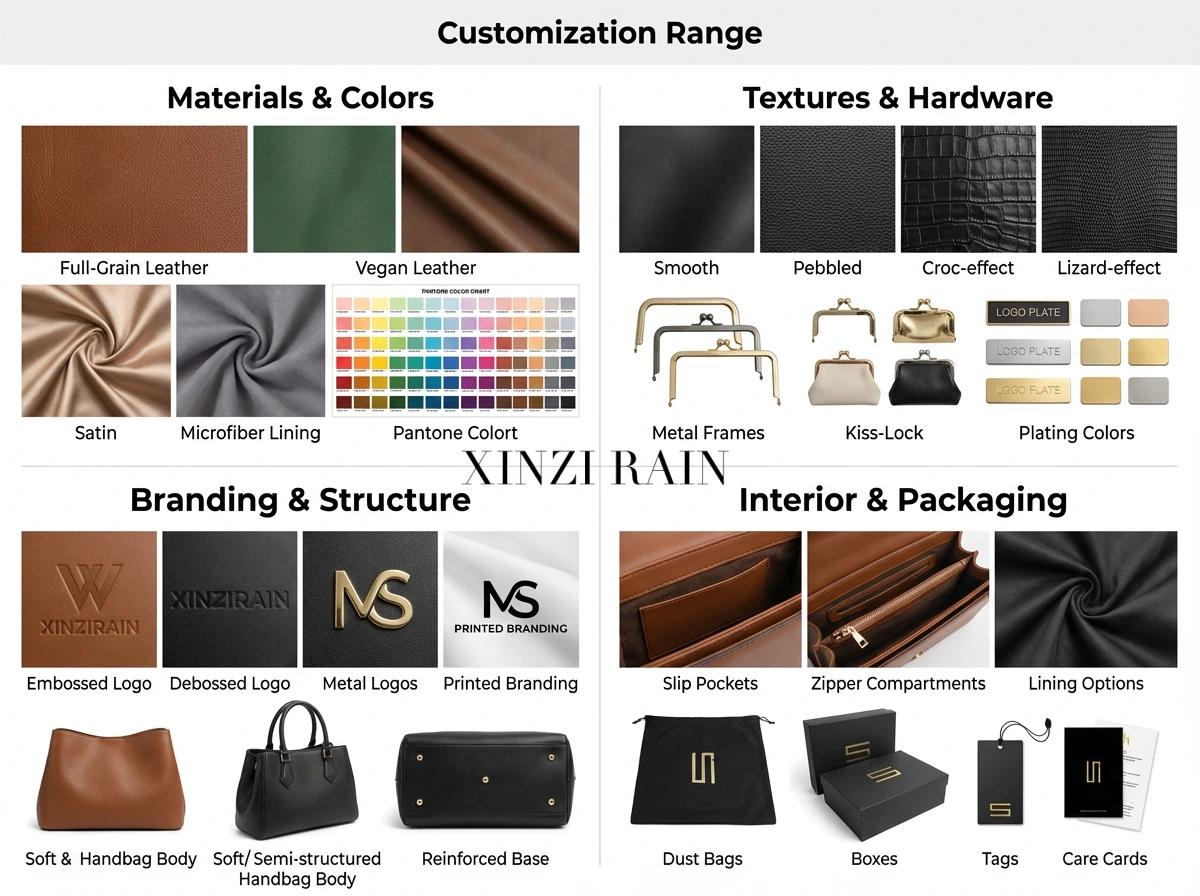

What You Can Customize

We support full customization across structure, materials, branding, and production details — allowing your bag designs to move from idea to scalable, market-ready products.

Customization options include:

Silhouette & Structure

Bag shape, capacity, rigidity, opening method, internal construction, and functional layout.

Materials

Genuine leather, suede, split leather, vegan leather, and mixed materials based on your market and compliance needs.

Texture & Finish

Pebbled, saffiano, smooth, crocodile-effect, vintage finish, or custom surface treatments.

Color Matching

Pantone color matching with batch control to ensure consistency from sampling to bulk.

Hardware

Zippers, buckles, chains, logo plates, zipper pulls, and custom hardware finishes.

Branding

Embossed or debossed logos, foil stamping, metal logos, woven labels, and printed branding.

Lining & Pocket Layout

Custom lining fabrics, inner pockets, compartments, card slots, and functional details.

Stitching & Edge Paint

Thread color, stitch density, edge paint thickness, durability, and finishing standards.

Packaging

Custom dust bags, branded boxes, hang tags, barcode labels, and retail-ready packaging.

Compliance Options

Material selections aligned with REACH and Prop 65 requirements for EU and US markets.

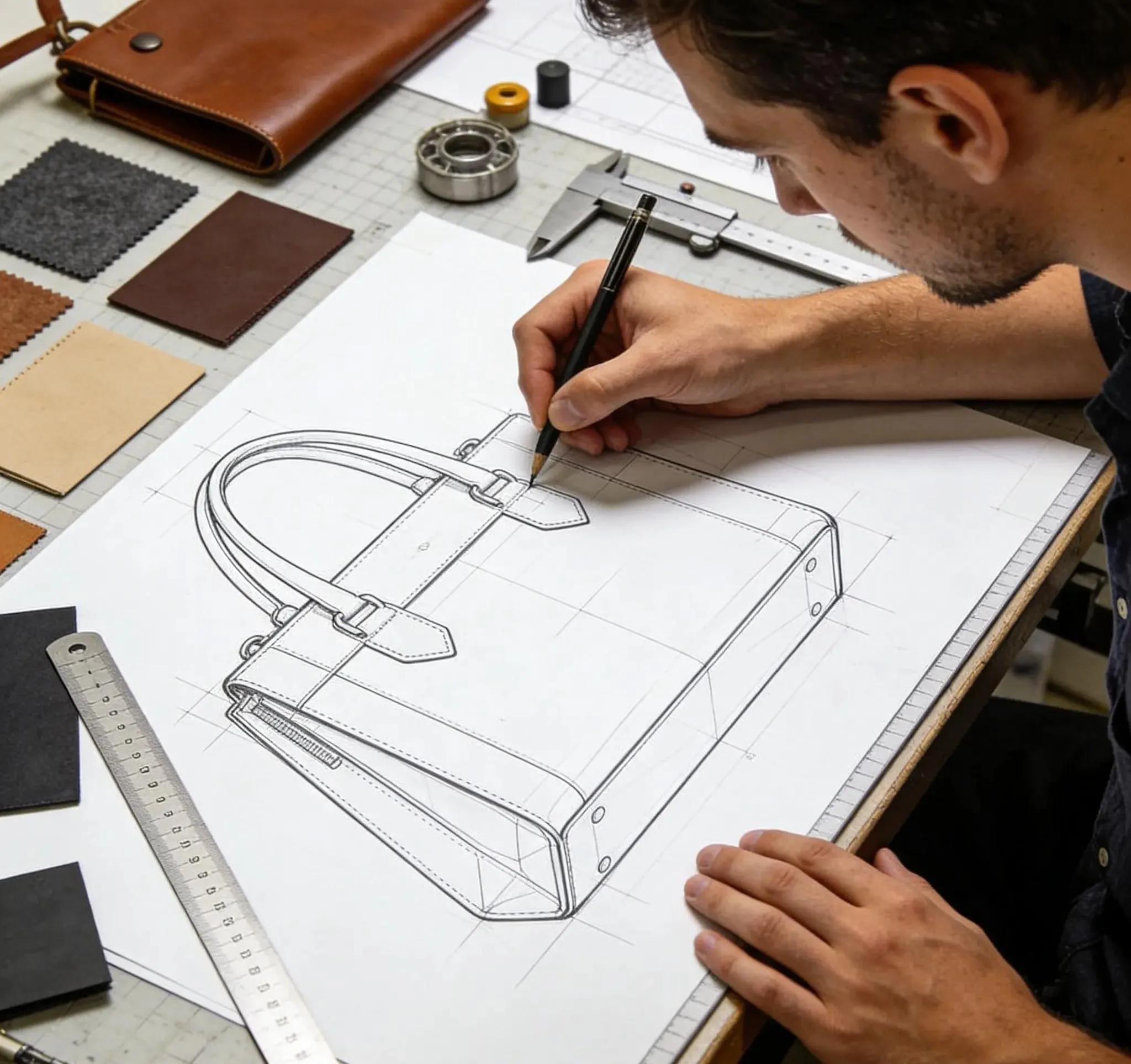

How You Can Start Your Design

We work with brands at different development stages. Choose the option that fits your current needs.

Option A — Tech Pack Ready

You provide a complete tech pack.

We evaluate feasibility, confirm materials and structure, quote accurately, and move directly into sampling.

Option B — Reference Sample or Photos

You share physical samples or reference images.

We analyze structure, develop patterns, recommend materials, and create a production-ready version.

Option C — Concept Only

You share sketches, mood boards, or ideas.

Our team supports design consultation, material suggestions, and structure planning to build the first prototype.

Our 7-Step Bag Development Process

Each step is managed internally to ensure design consistency, timeline control, and production accuracy.

Requirement Briefing

Share your design vision, target market, and functional requirements. Our team reviews your tech pack, sketches, or reference samples to align on project scope and timeline.

Material & Hardware Sourcing

We source premium leather, fabrics, zippers, buckles, and custom hardware based on your specifications. All materials meet REACH and Prop 65 compliance standards.

Pattern Making & Structure Evaluation

Our pattern masters create precise templates while engineers evaluate structural integrity, opening mechanisms, and internal compartments for optimal functionality.

Sample Development

First prototype is crafted with production-grade materials. You receive detailed photos and videos before physical sample shipment for initial review.

Sample Revision & Approval

Based on your feedback, we refine dimensions, stitching, hardware placement, and finishing details until the sample meets your exact standards.

Bulk Production (30–45 days)

Upon approval, we launch full-scale production with dedicated quality checkpoints at cutting, stitching, assembly, and finishing stages.

Packaging, Final QC & Worldwide Shipping

Each bag undergoes final inspection before custom packaging. We handle documentation and coordinate global shipping via air, sea, or express delivery.

Requirement Briefing

Share your design vision, target market, and functional requirements. Our team reviews your tech pack, sketches, or reference samples to align on project scope and timeline.

Material & Hardware Sourcing

We source premium leather, fabrics, zippers, buckles, and custom hardware based on your specifications. All materials meet REACH and Prop 65 compliance standards.

Pattern Making & Structure Evaluation

Our pattern masters create precise templates while engineers evaluate structural integrity, opening mechanisms, and internal compartments for optimal functionality.

Sample Development

First prototype is crafted with production-grade materials. You receive detailed photos and videos before physical sample shipment for initial review.

Sample Revision & Approval

Based on your feedback, we refine dimensions, stitching, hardware placement, and finishing details until the sample meets your exact standards.

Bulk Production (30–45 days)

Upon approval, we launch full-scale production with dedicated quality checkpoints at cutting, stitching, assembly, and finishing stages.

Packaging, Final QC & Worldwide Shipping

Each bag undergoes final inspection before custom packaging. We handle documentation and coordinate global shipping via air, sea, or express delivery.

MOQ & Lead Time Transparency

We provide flexible MOQs to support both growing brands and established labels.

- Sampling lead time: 30–45 days

- Bulk production lead time: 30–45 days

- MOQ: Flexible, depending on design, materials, and structure

Lead time may vary based on material availability, custom hardware, and complexity of construction. All timelines are confirmed before production begins.

Designed for Scale, Not Just Samples

We design with bulk production in mind — avoiding common issues where samples look good but fail in mass production.

- Pattern control and size consistency

- Material batch and color consistency

- Hardware durability and QC standards

- Multi-stage quality inspection before shipment

Your designs remain consistent from first sample to final delivery.

Compliance & Quality Assurance

We support international brands with clear quality and compliance processes.

- REACH-ready material options for EU markets

- Prop 65 support for US markets

- Quality documentation available upon request

- NDA and design confidentiality protection

Your designs, branding, and commercial information are fully protected.

Common Customization Requests

- Can you match our Pantone color across leather and edge paint?

- Can we redesign the internal pocket layout for functionality?

- Can you develop a new silhouette based on a reference bag?

- Do you offer vegan leather options for EU compliance?

- Can you add custom metal logos and zipper pulls?

If you have a specific requirement, our development team will assess and advise before sampling.

Start Your Custom Bag Project

Whether you're launching a new collection or scaling an existing design, XINZIRAIN provides reliable OEM/ODM customization with controlled quality and clear communication.